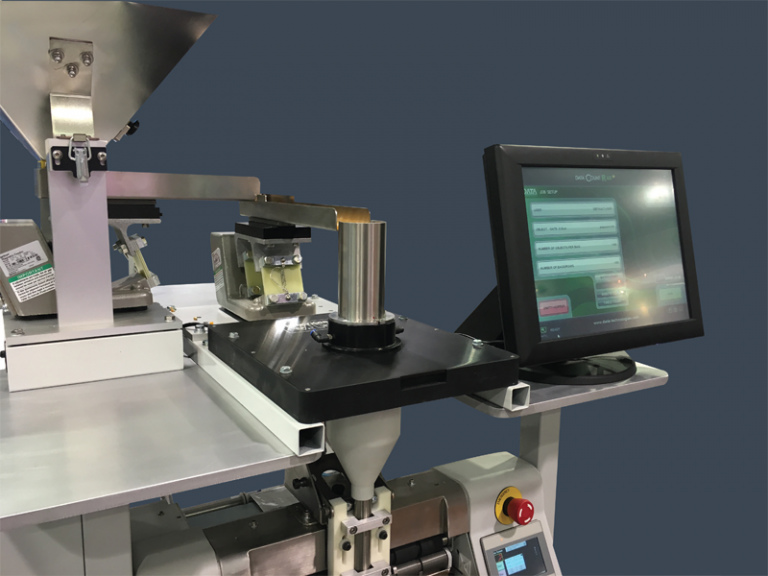

Clamco R1275 Vision Auto Counter System

Rollbag R1275 Automatic Bagger with Advanced Vision Counting System

Automatic bulk counting and bagging system combines speed and accuracy for packaging small products.

The Rollbag R1275 Vision Automatic Bagger is an extremely accurate automatic bulk counting and bagging system for packaging small parts. The compact system combines an industry proven automatic bagger with an advanced vision system. When used together the system can count and bag large quantities of small parts quickly.

The super accurate DATA vision system relies on advanced mathematical algorithms to count bulk parts ranging in size from 0.25? to 1? at up to 99.9% accuracy. The versatile high speed Rollbag R1275 Vision Automatic Bagger can fill and seal bags significantly faster than manual packaging, delivering exceptional efficiency and value. With the use of Rollbag brand pre-opened bags on a roll, fast packaging speeds may be achieved and bag size changeover can be accomplished quickly.

The Rollbag R1275 Vision Automatic Bagger is the fastest automatic bagger in its class, and is designed for multi-shift production. The exceptional performance of this automatic bagger is accomplished through smart design, a powerful PLC, and a unique stepper motor drive.

The Rollbag R1275 Vision Automatic Bagger includes a 1-year limited warranty, which is extended up to 5 years when exclusively using Rollbag brand pre-opened bags on a roll.

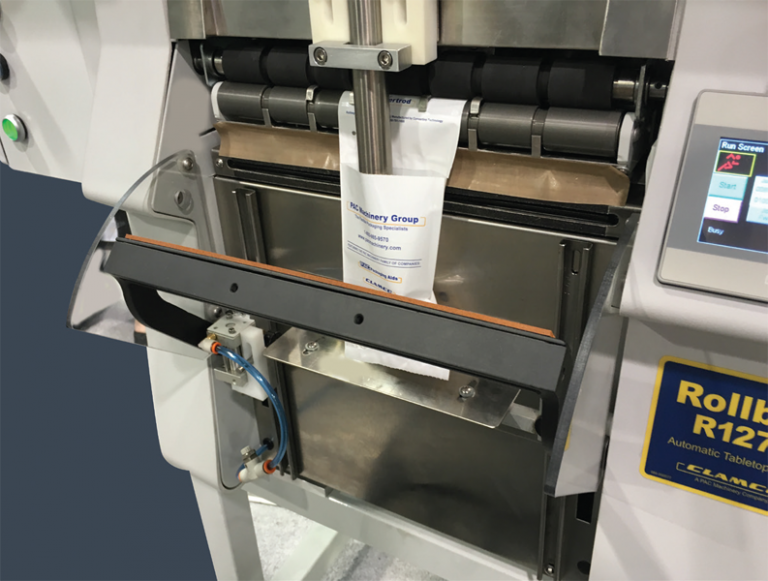

Thermal Transfer Printer to print information right on the bag

Product overfill reject system

Bag Spreader (Seal Flattener Fingers)

Spare Parts Kit

NiceLabel Pro Label Software

Additional options and customization is offered to meet your unique packaging applications. Please contact us for detailed information.

Operating Benefits

- Touchscreen interface with clear readable prompts and alarms

- 3D imaging for 99.9% accuracy on parts that are 0.25?–1? in size

- Double track feeding for product separation prior to counting

- Articulating funnel ensures product drops directly in the bag

- Bag support stabilizes bag during loading and removes it

from packaging area at end of cycle - Bag sensor ensures every bag is open before filling the product

- Print directly on each bag via thermal transfer printer (optional)

- Product overfill reject system (optional)

Maintenance Benefits

- Off the shelf modular components for easy replacement

- Remote network access for improved troubleshooting

- Self-diagnostics ensure quick problem-solving

- Reliable components designed for multi-shift production

Set Up Features

- Easy changeover for different sizes – no special tools required

- PLC with multiple job storage

- Batch counters, packaging statistics & process parameters

- Uses Rollbag pre-opened bags for fast bag size changeover

- Integrated frame with casters for added mobility

Safety Features

- Low pressure seal bar closing with obstruction detection system for improved operator safety

- Unobtrusive guards

- Prominent emergency stop button

- 220V designed to meet CE requirements