Clamco 4C & 6C Combo Shrink Wrap Machines

Heavy duty combo shrink packaging machines

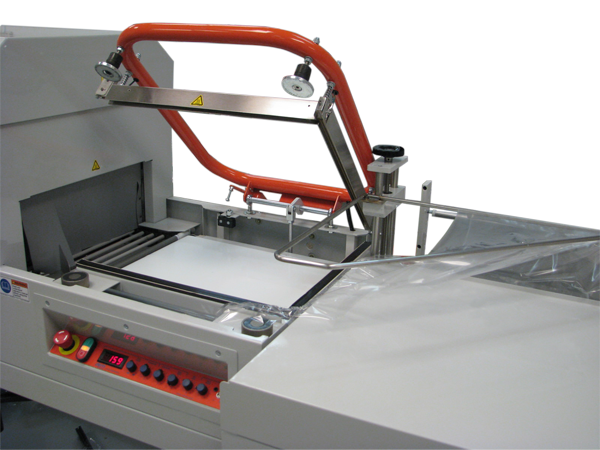

The Clamco 4C and 6C combo shrink packaging machines combine a heavy-duty L-bar sealer and shrink tunnel for packing, sealing, and shrink wrapping a variety of products. Clamco combo shrink packaging systems can be used with a wide range of films due to their precise temperature and speed controls. These combo shrink wrap machines come with a standard power take-away system and are available with a sealer arm that works manually, pneumatically, or with a motor.

Built for performance

The robust design of the Clamco systems provides the framework for greater productivity and ensures consistently strong seals. The digitally temperature controlled tunnel provides for consistent shrink. The use of integrated application-specific controls allow for easy and fast operator set-up and provides for years of trouble-free operation.

Industry-leading durability and technology

The Clamco 4C and Clamco 6C combo machines are heavy-duty shrink packaging systems engineered for 24/7 use. Designed to minimize maintenance and provide consistent strong seals they can be used with a wide range of films. The Clamco L-bar sealers offer a hot knife seal bar option for sealing PVC and polyethylene films. The Clamco system has a single adjustable height control for the product take-away and tunnel conveyor to deliver smooth product transfer. The height of the tunnel chamber is adjustable, increasing shrink efficiency for short products. Additionally, Green Mode allows for the Clamco 4C and Clamco 6C to slow down and conserve energy when the machine remains idle for several minutes.

Clamco 4C and 6C Combo L-bar sealers and shrink tunnels are made in the USA and include a 3 year limited warranty.

Financing Options from $180/month

- Unique temperature controlled seal system provides consistent strong seals and increases the life of the seal wire when compared to traditional systems

- Power take-away and tunnel conveyors with a single height adjustment provide for smooth product transfer

- Heavy duty 24/7 shrink system designed for rugged industrial environments and requires minimal maintenance

- Convenient scrap drop and collection area for trimmed film, which reduces clean-up time

- Live/dead roller system allows the use of a wide variety of films

- Seal temperature control provides repeatability of seal performance

- Dwell control provides additional flexibility for utilizing a wide range of films

- Heavy duty magnetic hold down to insure consistent seal pressure

- Easy-to-use operator controls for fast and easy set-up

- Quick adjustment facilitates centering of the seal on the product

- Digitally controlled tunnel with 360 degree air circulation for consistency and maximum performance

- Adjustable airflow and variable tunnel conveyor speed enhances shrink performance

- Automatic cool down and shutoff extends the life of the machine

- Adjustable unitized package tray and film cradle with pinwheel perforator

- Film cradle can accommodate up to a 24” wide roll of film on the DEM 4 and up to a 32” wide roll of film on the DEM 6

- Tunnel curtain design minimizes heat loss and maintains tunnel temperature consistency

- Designed to meet CE requirements

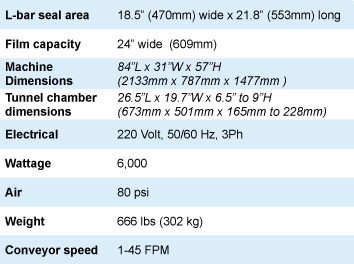

Specifications

Options

- Automatic pace operation using pneumatic or motorized seal arm

- Variable speed power take-away conveyor

- Seal Flattener to minimize wrinkles during sealing

- 400volt, 50/60 Hz operation

- 4” (100mm) tunnel opening extension

- 1” roller spacing for small or odd size products

- Large jaw opening (DEM-6 only)

- Scrap take-up reel

- Exit transfer conveyors

- Adjustable height roller conveyors

- Product accumulation table

- Blower table for assisting product loading

- Motorized film unwind

- Double film cradle

- Tunnel conveyor with Teflon belt

- Machine tray with rollers for heavy products

- Clamco 4C & 6C Combo - L-Bar Sealer and Tunnel Shrink Wrap System

- Clamco 4C Combo Combination L Bar Sealer & Heat Tunnel - Machine for Shrink Wrapping Boxes

- Hot Knife L-Bar Sealer with Automatic Closing - 4C and 6C Combo Shrink Wrap Machine

- Hot Knife L-Bar Sealer with Automatic Closing - 4C and 6C Combo Shrink Wrap Machine