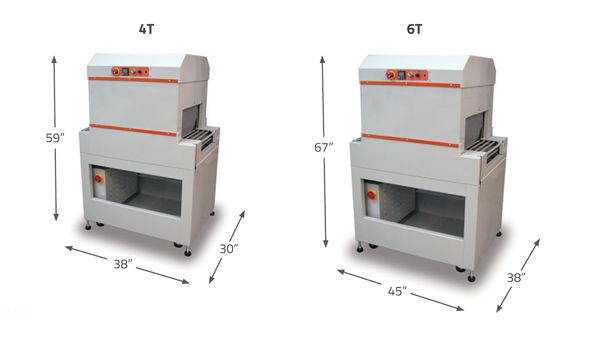

Clamco 4T & 6T Heavy Duty Shrink Tunnel

Engineered For Performance

The Clamco 4T and 6T Heavy Duty Heat Shrink Tunnels are engineered with many features to offer a combination of performance and dependability. Due to their precise temperature and speed controls, Clamco heavy duty tunnels are perfect for shrinking a wide range of films, from the lightest polyolefin to the toughest polyethylene films. Combine this durable shrink tunnel with the heavy duty Clamco L-Bar Sealer to create a complete shrink system.

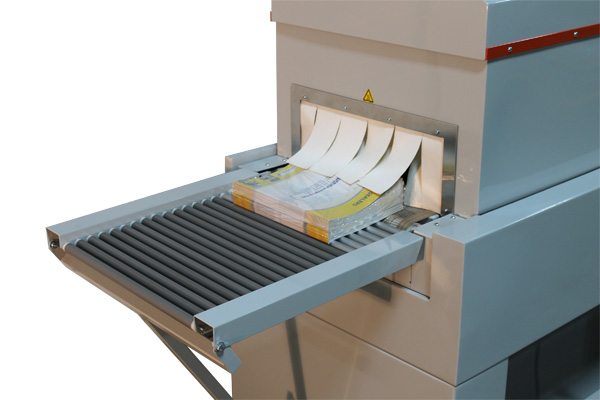

The tunnel features include digital temperature control for precise shrink wrap performance, adjustable airflow and variable tunnel conveyor speed. These tunnels are equipped with long-life blowers and 360° airflow to further enhance control of film shrink. The automatic cool down and shut off extend the life of the tunnel. The tunnel curtain design and tunnel insulation minimize heat loss, maintain tunnel temperature consistency and keep outside tunnel panels cooler. The tunnel conveyor features 1.5-inch roller spacing that works well with large to small products and quick change live/dead rollers.

The Clamco 4T and 6T tunnels operate 24/7 with unique microprocessor controls for consistent shrink on a variety of applications. Count on Clamco heavy duty shrink tunnels for dependable performance.

The Clamco 4T and 6T Tunnels are made in the USA and include a 3-year limited warranty.

Operating Features

- Heavy duty console for stability and strength

- 360° air flow with dual blowers to enhance film shrink

- Slide dampers in the tunnel help adjust the airflow characteristics

- Double entry and exit curtains for consistent temperature

- Fully insulated helps maintain consistent heating

- Automatic cool down extends the life of the heating element

- 1.5? roller spacing for smaller products

- Variable speed live/dead roller belt conveyor for variable conveyor speeds

- Digital temperature control for accurate temperature readings

- 3-year limited warranty

Safety Features

- Leveling foot pads and casters for mobility, stability, and safety

- Emergency stop switch if an emergency occurs during operation

- Main breaker switch designed to trip before electrical draw exceeds carrying capacity

- Over temperature safety ensures tunnel cooldown if machine reaches excessive temperature

Operating Options

- External cooling fans at the end of the tunnel to complete shrinking process and cool product

- 1? Roller spacing option accommodates smaller products and ensures significant tunnel turbulence

- 4? Extended height tunnel opening clearance for taller packages

- Variable air velocity control for operator control of internal tunnel wind direction

- Mesh Belt Conveyor used in place of a standard roller belt for smaller and lighter products

- Exit Conveyor allows time for a complete shrink

- Roller Transfer Conveyor for transition from the sealer to the tunnel