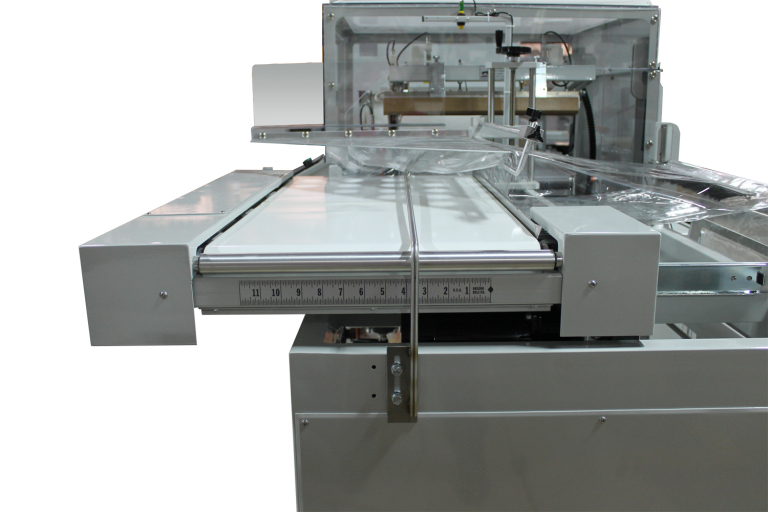

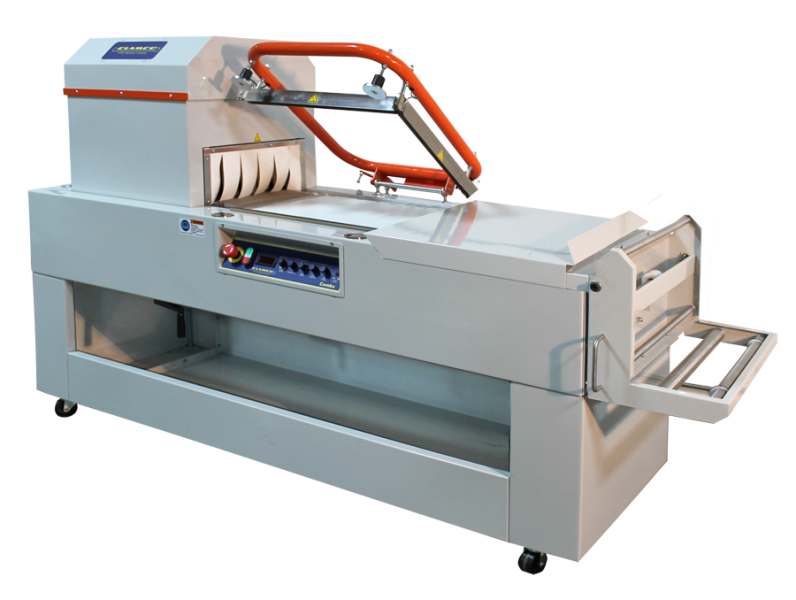

Clamco 6700 GLX Automatic L Bar Sealer

When Speed and Versatility Matter

The 6700GLX automatic L-bar sealer delivers the features and performance today’s packaging operations demand. The 6700GLX includes a PLC, touchscreen interface and I/O diagnostics, 20 package job memory, self-adjusting trim take-up wheel, easy load front film cradle, and micro perforators for uniform air evacuation. The result is an automatic L-Bar sealer with outstanding speed, throughput, and performance to maximize productivity.

Streamlined interface

The easy to read touchscreen operator interface includes built-in self-diagnostics, production tracking, and machine fault memory to ensure maximum performance. Product alignment guides and variable speed conveyor up to 100 feet/min ensures production of up to 40 packs/min*. The front load film cradle mounted strategically just 8” off the floor allows ergonomic film roll changeovers with added space saving (the machine can be positioned against a wall). A film splitter and static eliminator work to reduce blocking of the film to allow smooth film feed throughout the machine. Horizontal and vertical sensors combined with a state-of-the-art mushroom style hot knife sealing system and film cutoff provides consistent seals.

Built for 24/7 production

A heavy-duty solid frame construction is manufactured for today’s demanding production outputs. The 6700GLX automatic l-bar sealer is engineered and designed for 24/7 operation. Included with the frame is heavy duty casters and levelers for portability. Enclosed guarding ensures operator safety, and like other Clamco shrink products, this unit complies with CE regulations for improved safety and design.

The Clamco 6700GLX automatic L-bar sealer is made in the USA and includes a 2-year limited warranty.

Financing Options from $560/month

* Speed is dependent upon package size

Features & Specs

- Allen-Bradley microprocessor or base controller (PLC)

- Touch-screen interface with diagnostics

- Product memory for up to 20 package configurations

- Heavy-duty hot knife sealing system with 18? x 23? seal area

- Lower film cradle with film splitter and static eliminator

- Adjustable height sealing jaws for products up to 8? high

- Product alignment guides

- Horizontal and vertical product sensors

- Variable speed conveyors—15 to 100 fpm

- Package speed up to 40 per minute (depending on package size and film type)

- Self-adjusting scrap take-up reel

- Micro-Perf perforators for uniform air evacuation

- Variable-speed film unwind

- 23? maximum film width

- Casters and levelers

- Made in U.S.A.

- One year limited warranty

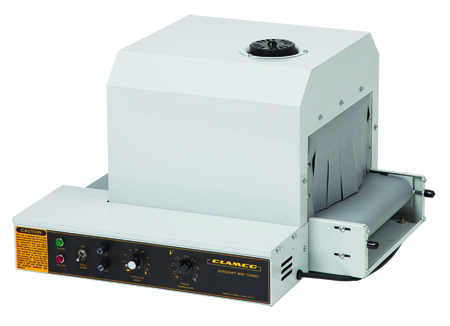

Options

- Various seal knife options available

- Tunnel controls integrated through PLC and interface (7221 and 6022 Tunnels)

- Closing conveyor

- Printed film registration

- Split conveyor for product staging

- Light package takeaway